As every field service business knows, effective data utilization is essential for high-quality field service management.

And as technology advances, the implementation of proactive and predictive maintenance powered by AI is rapidly improving the field service industry – as we see with our clients every day. Indeed, the global predictive maintenance market is projected to grow to $47.8 billion by 2029, at a CAGR of 35.1%.

Here, we explore how AI enhances these maintenance strategies, leading to improved operational efficiency, customer service, and technician performance.

Understanding Proactive and Predictive Maintenance

So what exactly is AI-powered proactive and predictive maintenance?

Proactive maintenance involves taking preemptive actions to ensure equipment reliability and performance, while predictive maintenance leverages data and AI to predict and prevent equipment failures before they occur.

Unlike reactive maintenance, which addresses issues only after they happen, and preventive maintenance, which relies on scheduled checks, proactive and predictive maintenance utilize real-time data to foresee potential problems and intervene early. This approach is crucial for minimizing downtime, maximizing productivity, and reducing costs on labor, materials, and expenditures.

The Limitations of Traditional Maintenance Models

Traditional maintenance models, more reactive in nature, have significant limitations:

- Reactive Maintenance: Repairs are only made after equipment fails, leading to unexpected downtime and costly disruptions. This approach often results in higher expenses due to emergency repairs and unplanned operational halts.

- Scheduled Maintenance: Fixed maintenance schedules can be inefficient, causing either unnecessary maintenance or unexpected failures. Regular maintenance checks might not always detect underlying issues that could lead to failures between scheduled intervals.

- Limited Data Utilization: Decisions are often based on historical data and manual inspections rather than real-time insights, resulting in less effective maintenance strategies. This approach fails to harness the potential of modern data analytics and AI to foresee and prevent issues.

The Benefits of AI-Powered Proactive and Predictive Maintenance

As compared to the older model, AI-powered proactive and predictive maintenance offer numerous benefits:

- Rapid Data Usage: AI and machine learning analyze vast amounts of data to predict equipment failures. By collecting data from sensors, ERP systems, and historical records, AI provides actionable insights that help prevent downtime.

- Preventing Downtime: Proactive and predictive maintenance reduce unexpected outages and their cascading effects on operations. As Deloitte put it, “by anticipating and avoiding a machine failure, the enterprise could prevent cascading impacts that could slow other operations and cause costly outages.”

- Improving ROI: Extending the lifespan of equipment and optimizing resource use improves return on investment (ROI). Proactive and predictive maintenance can help businesses “extract more value from existing investments”

- Empowering the Workforce: AI enables maintenance teams to shift from reactive repairs to proactive prevention, allowing them to focus on higher-value tasks. This shift can lead to better workforce management, more efficient use of human resources, and improved morale among technicians.

- Enhancing Safety and Quality: Timely maintenance ensures that safety standards and product quality are maintained. Proactive and predictive maintenance can “improve the safety of enterprise operations” and “enhance quality control through proactive intervention”.

And the data is clear: Predictive maintenance can reduce maintenance costs by 8% to 12% compared to preventive maintenance, and up to 40% over reactive maintenance. Implementing predictive maintenance can decrease unplanned downtime by up to 50%. And AI-driven predictive maintenance has been shown to increase productivity and efficiency by 25%.

By Persona: The Practical Applications of Predictive Maintenance

Predictive maintenance improves various aspects of field service management:

For the Customer Experience:

- On-Demand Service Requests: Customers can request services via mobile devices, providing convenience and immediacy. This flexibility meets the high expectations of modern consumers who demand quick and easy service access.

- Real-Time Updates: Customers receive timely updates on service status, enhancing transparency and satisfaction. Real-time notifications about technician arrival times and job progress keep customers informed and reduce uncertainty.

- Direct Communication: Enhanced communication with field agents leads to higher customer satisfaction and trust. Direct channels for feedback and support help resolve issues faster and build stronger customer relationships.

For Dispatcher Efficiency:

- Real-Time Monitoring: Dispatchers can track field agent locations and availability in real-time, ensuring optimal resource allocation. This capability allows for dynamic scheduling adjustments based on current field conditions.

- Optimal Resource Allocation: AI insights help assign the right technician for each job, improving efficiency. Predictive maintenance analytics can suggest the best-fit technician based on skill sets, proximity, and availability, ensuring quicker resolution times.

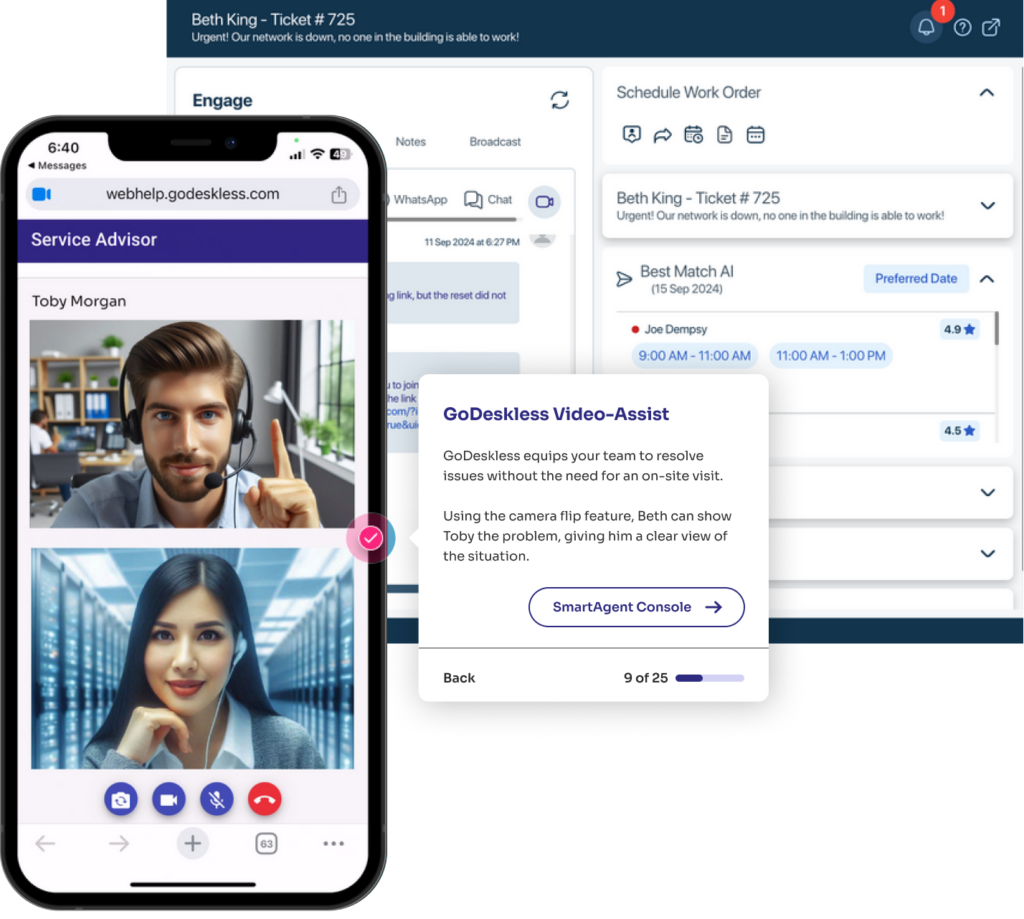

- Collaboration Tools: Tools like video assist and smart knowledge bases support efficient problem resolution. These technologies enable dispatchers and technicians to collaborate effectively, leveraging collective expertise to solve complex issues on the first visit.

For Field Agent Preparedness:

- Comprehensive Job Information: Detailed pre-visit diagnostics and real-time inventory management ensure agents are well-prepared. Access to accurate and up-to-date information helps technicians understand the issue before arriving on site.

- Improved First-Time Fix Rates: Equipped with comprehensive information, agents can resolve issues on the first visit, increasing efficiency. This reduces the need for follow-up visits and enhances customer satisfaction.

How GoDeskless Supports Predictive Maintenance

At GoDeskless, our mobile-first field service management platform leverages AI and data analytics to transform service delivery. We seamlessly integrate with existing systems, providing real-time updates and offering features like service requests via SMS or WhatsApp, SmartAgent consoles, video assist, and a smart knowledge base.

These tools enhance customer convenience and transparency, improve dispatcher efficiency through real-time monitoring and optimal technician assignment, and ensure field agents are well-prepared with comprehensive job information, leading to reduced downtime and higher first-time fix rates.

By adopting AI-powered proactive and predictive maintenance, businesses can stay competitive, reduce unexpected outages, and extend the lifespan of their equipment. Our platform not only supports these advancements but also empowers your workforce, allowing them to focus on higher-value tasks and improve overall service quality.